Top 2025 Rocker Switch Types You Need to Know for Your Projects

In the realm of electrical projects, the choice of components can significantly impact both functionality and user experience. Among the vital components that play a critical role in control systems, the Rocker Switch stands out as a popular option for a variety of applications. Known for its simple yet effective design, the Rocker Switch allows users to easily toggle devices on and off, making it an essential part of countless electrical setups, from household appliances to industrial machinery.

As we advance into 2025, understanding the different types of rocker switches available becomes increasingly important for designers and engineers alike. Each type comes with its unique features and specifications, catering to different needs and environments. Whether it’s the momentary rocker switch for quick actions or the illuminated varieties for enhanced visibility, familiarity with these designs can enhance project efficiency and performance.

This article will delve into the top rocker switch types you need to know for your projects, providing insights into their functionalities, applications, and installation considerations. By arming yourself with this knowledge, you can ensure your projects not only meet high standards of safety and reliability but also excel in usability and design.

Types of Rocker Switches: Overview and Applications

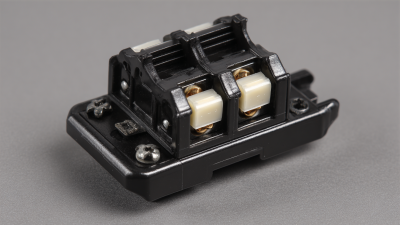

Rocker switches are essential components in various electrical and electronic projects, serving as a simple yet effective means of controlling devices. They come in various types, each tailored for specific applications. The most common types include single-pole single-throw (SPST), single-pole double-throw (SPDT), and double-pole double-throw (DPDT) switches. SPST switches are typically used for basic on/off functions, making them perfect for everyday household applications. SPDT switches allow for switching between two circuits, making them ideal for devices that need to toggle functions. Meanwhile, DPDT switches can control two different currents with a single switch, making them versatile for more complex circuitry.

When selecting a rocker switch for your project, consider the voltage and current ratings, as they will affect the switch's performance and longevity. Additionally, pay attention to the mounting style, as this can determine how easily you can integrate the switch into your design.

Tips for choosing the right rocker switch include checking the durability ratings, especially if the switch will be subjected to frequent use. Ensure that the switch is rated for the specific load it will control to prevent any electrical mishaps. Also, consider the aesthetic factors, such as color and illumination options, which can enhance the overall look of your project while providing practicality.

Top 2025 Rocker Switch Types: Overview and Applications

This chart illustrates the various types of rocker switches and their estimated applications in projects for the year 2025. The data reflects their popularity and use in different scenarios.

Choosing the Right Rocker Switch for Your Project Needs

When embarking on a project that involves electrical components, selecting the right rocker switch is crucial. Understanding the different types of rocker switches available can significantly impact the functionality and safety of your project. Rocker switches come in various sizes, styles, and configurations, each designed to fulfill specific requirements. For instance, some may offer a simple on/off function, while others incorporate additional features like LED indicators for enhanced visibility. Assessing the specific needs of your project—be it voltage requirements, environmental conditions, or aesthetic preferences—will guide you in selecting the most appropriate switch.

Moreover, it's essential to consider the switch's mounting style and compatibility with your project. Rocker switches can be panel-mounted or PCB-mounted, each suited for different applications. Additionally, pay attention to the electrical ratings and certifications associated with the switch; these factors determine the switch’s reliability and safety under operating conditions. By carefully evaluating these characteristics, you can ensure that the rocker switch will not only meet your project's needs but also provide long-lasting performance.

Electrical Specifications: Voltage and Current Ratings

When selecting rocker switches for your projects, understanding the electrical specifications is essential. The two primary factors to consider are voltage and current ratings, which determine the switch's operational capacity and safety. Voltage ratings indicate the maximum electrical potential the switch can handle without risking failure, while current ratings specify the maximum amount of electrical flow it can safely conduct. Selecting switches with appropriate ratings ensures they operate efficiently and reduces the risk of overheating or electrical failures.

Different applications may require specific voltage and current ratings. For example, low-voltage applications in hobby electronics may only need switches rated for 12V and a few amps, while industrial machinery may require switches rated for 480V and higher currents. It's crucial to match the switch ratings with the power supply and load demands of your project. Additionally, consider the inrush current, which can be significantly higher than the steady-state current, particularly in devices with inductive loads. This consideration ensures that the selected rocker switch can handle transient conditions without compromising performance or safety.

Design Variations: Single Pole, Double Pole, and More

When selecting rocker switches for your projects, understanding the different design variations is essential. Among the most common types are single pole and double pole switches. A single pole switch is used to control a single circuit and is ideal for simple on/off applications. On the other hand, double pole switches allow you to control two separate circuits simultaneously, making them perfect for applications requiring more power or where two distinct feeds are necessary.

For those looking for versatility, toggle or momentary rocker switches provide additional options. Toggle switches remain in their last position until manually changed, while momentary switches only stay activated while pressed. This flexibility can be crucial in various applications, especially in automotive or appliance settings.

**Tips:** When choosing rocker switches, consider the voltage and current ratings to ensure they can handle your project's requirements. Always think about the switch's location and ease of access, as frequently operated switches should be positioned for convenience. Additionally, check the switch's durability and environmental resistance, especially for outdoor or harsher applications, to ensure longevity and reliable performance.

Installation Tips and Best Practices for Rocker Switches

When it comes to installing rocker switches, understanding the best practices is crucial for ensuring longevity and reliability in electrical projects. According to the latest industry report by MarketsandMarkets, the global market for switches, including rocker types, is projected to reach $23.9 billion by 2025, highlighting the growing importance of quality installations. A well-installed rocker switch not only enhances the user experience but also minimizes the risk of electrical failures and associated hazards.

During installation, it's essential to select the right type of rocker switch for your specific application. Consider factors like voltage ratings and environmental conditions, as switches exposed to moisture or heat may require sealed or rated components. Proper wiring techniques, such as avoiding excessive strain on terminals and ensuring solid connections, can significantly reduce the chance of connectivity issues. The National Electrical Code (NEC) emphasizes the importance of using switches that match the application's electrical characteristics to avert potential overloads.

Furthermore, implementing proper mounting techniques can also elevate the performance of rocker switches. Ensure adequate spacing between switches and avoid overcrowding in electrical panels to facilitate heat dissipation. Regular maintenance checks can help identify wear and tear before it leads to more significant problems. Following these installation tips and best practices can not only enhance the performance of rocker switches but also contribute to the overall efficiency and safety of electrical systems.

Top 2025 Rocker Switch Types You Need to Know for Your Projects

| Switch Type | Current Rating (A) | Voltage Rating (V) | Applications | Installation Tips |

|---|---|---|---|---|

| Standard Rocker Switch | 10 | 250 | Home appliances, DIY projects | Ensure proper alignment with panel cutout |

| LED Rocker Switch | 15 | 12 | Vehicles, boats, motorcycles | Check polarity of LED connections |

| Mini Rocker Switch | 5 | 120 | Lighting, low-power devices | Use lightweight wires for easy installation |

| Tamping Rocker Switch | 20 | 240 | Industrial equipment, machinery | Secure connections must be verified |

| Waterproof Rocker Switch | 10 | 12 | Outdoor lighting, marine applications | Ensure sealing is intact during installation |

Related Posts

-

Elevate Your Experience: The Global Success of Upgraded Chinese Manufacturing with Best Electrical Rockers

-

Innovative Solutions for Best Round Rocker Switch Applications

-

How to Upgrade Your Home with Rocker Light Switches for Modern Living

-

Understanding the Differences Between Single and Double Rocker Switches for Your Needs

-

Why You Should Choose Led Rocker Switch for Your Next Project

-

Premium Quality Momentary Rocker Switches from a Leading Chinese Manufacturer