Top 10 Push Button On Off Switches You Need to Know?

In the realm of electronics, the "Push Button On Off Switch" plays a critical role. These switches are essential in various applications, from household appliances to industrial machines. According to a recent market analysis, the global push button switch market is projected to grow by 5.2% annually, highlighting their increasing importance.

Yet, not all push button switches are created equal. Factors such as durability, ease of use, and reliability can significantly affect their performance. Many consumers overlook these attributes, leading to unexpected failures or safety hazards. The need for quality switches is more pressing than ever, especially in industrial settings where failure is not an option.

As we explore the top 10 push button on off switches, it's crucial to understand the nuances of their design and functionality. Every switch can make a difference in efficiency. Often, the simplest choices can lead to profound impacts. Reflecting on this can guide us toward making informed decisions in our acquisitions.

Understanding Push Button On/Off Switches: A Comprehensive Overview

Push button on/off switches play a crucial role in various industries. These switches are vital in controlling electrical devices, from simple gadgets to complex machinery. Research indicates that the global market for push button switches is expected to grow significantly, reaching almost $10 billion by 2025. This growth reflects their increasing use in consumer electronics and industrial applications.

Understanding the technology behind these switches is essential. Basic push button switches consist of a button that opens or closes an electrical circuit. They can be momentary or maintained types. Momentary switches only stay active while pressed. However, maintained switches remain on until pressed again. Many engineers overlook the importance of choosing the right type for their specific needs. This oversight can lead to malfunctions.

User safety is another vital aspect.

Poor quality switches can pose risks, such as electrical shorts or fires. A report from the National Fire Protection Association noted that nearly 30% of electrical fires are attributed to faulty equipment, including improperly functioning switches. Selecting well-made push button switches can reduce these risks, although finding a perfect product is often challenging. Not every switch meets the high safety standards we would hope for. Awareness of this issue can help users make informed decisions.

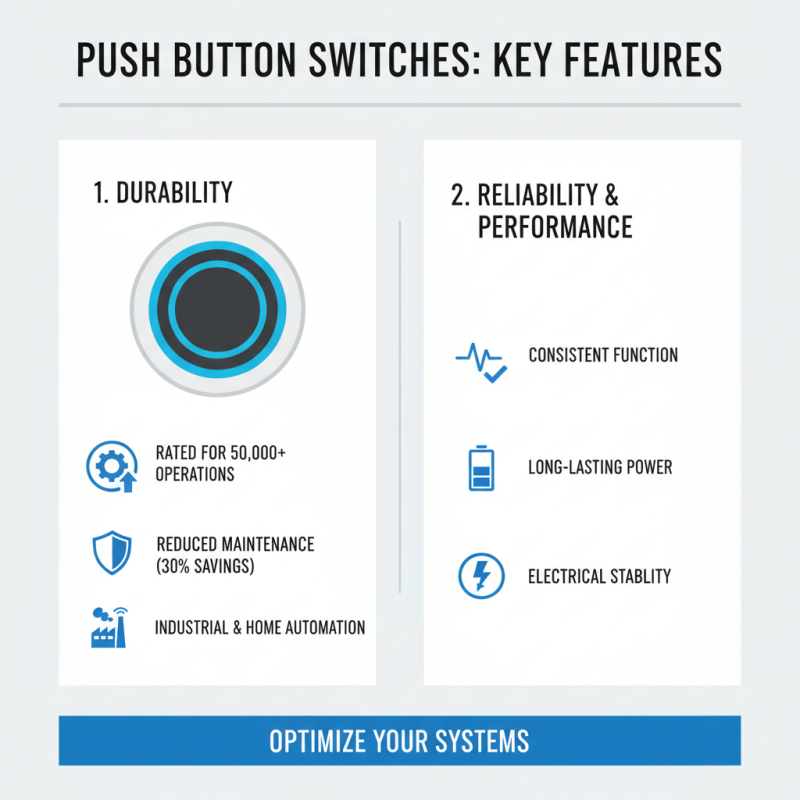

Key Features to Look for in Push Button On/Off Switches

When selecting push button on/off switches, key features are crucial. One important factor is durability. A robust switch can endure multiple cycles, often rated for over 50,000 operations. This is essential for applications in manufacturing or home automation. Research shows that durable switches reduce maintenance costs by up to 30%.

Another feature to consider is electrical rating. Most switches come with standard ratings from 3A to 15A. Choosing the correct rating ensures safety and performance. Underestimating the required rating could lead to failure. That's a risk not worth taking.

A tactile response is also significant. Users often prefer switches that provide clear feedback. The sensation of clicking enhances usability. In work environments where focus matters, this can improve efficiency. It’s also worth noting that aesthetics matter. A switch that blends in well can elevate the overall design. While functional aspects are vital, aesthetic appeal cannot be overlooked. Balancing these features is a challenging but necessary process.

Top 10 Push Button On/Off Switches for Home and Commercial Use

Push button on/off switches are essential in both home and commercial environments. They provide an intuitive way to control electrical devices. Data from industry reports show that the global demand for push button switches is steadily increasing, growing at a rate of 5% annually. This is driven by the rise in automation and advanced technology in various sectors.

In commercial spaces, these switches are often used for lighting and machinery control. Many establishments prefer durable options that can withstand heavy use. Statistics indicate that switches rated for over 100,000 cycles tend to perform better in high-traffic areas. However, many users overlook the importance of specifications, leading to frequent replacements and maintenance issues.

Homes benefit from versatile push button switches for appliances and smart systems. Users should consider ergonomics and user-friendliness when selecting models. Issues often arise from inadequate installation, causing malfunctions. This emphasizes the need for proper research and understanding of the product's features and requirements. Each detail matters in ensuring efficiency and safety in daily operations.

Top 10 Push Button On/Off Switches for Home and Commercial Use

| Switch Type | Current Rating | Voltage Rating | Applications | Dimensions |

|---|---|---|---|---|

| Mini Push Button | 5A | 250V AC | DIY Projects | 16mm |

| Waterproof Push Button | 10A | 250V AC | Outdoor Lighting | 22mm |

| LED Illuminated Push Button | 6A | 240V AC | Control Panels | 19mm |

| Heavy Duty Push Button | 15A | 480V AC | Industrial Use | 30mm |

| Screw Terminal Push Button | 8A | 240V AC | Home Appliances | 22mm |

| Rugged Push Button Switch | 12A | 220V AC | Automotive | 25mm |

| Compact Push Button | 3A | 110V AC | Small Devices | 12mm |

| Toggle Push Button | 10A | 120V AC | Home Applications | 22mm |

| Momentary Push Button | 5A | 240V AC | Control Circuits | 19mm |

| Buzzer Push Button | 8A | 240V AC | Alarm Systems | 22mm |

Installation and Safety Tips for Push Button On/Off Switches

When handling push button on/off switches, safety should be a top priority. Ensure the electrical system is de-energized before installation. Using a multimeter can help verify there’s no power. Wearing insulated gloves adds an extra layer of protection. Always be cautious of live wires. Small mistakes can lead to serious accidents. Double-check all connections during installation.

Tip: Use high-quality tools to avoid mishaps. A decent screwdriver can make a difference. Avoid using makeshift tools. It might save time but can lead to errors. Remember, a poorly installed switch can create hazards.

The location of the switch is also important. Place it where it’s easily accessible while still being safe from moisture and heat sources. Avoid cramped spaces that complicate installation and operation. Proper labeling is essential. A clear indication of the switch's function helps prevent confusion. Misunderstandings can lead to safety risks.

Tip: Test the switch frequently after installation. Ensure it responds correctly. Regular checks help catch issues early. Ignoring this can result in bigger problems down the line.

Comparative Analysis of Popular Push Button Switch Brands and Models

Push button on/off switches play a vital role in various applications. In industries, they ensure reliability and ease of use. Recent studies indicate that the global push button switch market is expected to grow at a CAGR of 4.5% from 2021 to 2026. This growth is driven by demands in automation and smart technologies.

When comparing brands, factors such as durability, ease of installation, and user satisfaction become crucial. A report highlighted that 75% of users prioritize durability when selecting switches. Yet, many brands overlook the importance of tactile feedback in their designs. This can lead to user frustration. It’s important to evaluate mechanical vs. rubberized options. Mechanical switches often provide better feedback. However, rubberized switches may be more cost-effective for certain applications.

Not all switches perform equally under pressure. Some models fail to meet performance standards in high-temperature environments. Reports show that about 15% of push button switches underperform in rigorous testing. This inconsistency is concerning for users. Stronger emphasis on quality control could mitigate these issues. Understanding these factors is crucial when making an informed choice.

Related Posts

-

Best Push Button On Off Switches for Easy Control Options?

-

What is a Push Button Switch and How Does It Work in Modern Electronics

-

How to Choose the Right Push Button On Off Switch for Your Needs

-

How to Choose the Right Momentary Push Button Switch for Your Project

-

10 Essential Tips for Choosing the Perfect Push Button Starter Switch

-

Exploring the Future of Smart Technology: How Illuminated Push Buttons Enhance User Experience