Top 10 Latching Push Button Switch Options for Your Projects?

In the world of electronics, the Latching Push Button Switch is a critical component in various applications. According to a recent market analysis by Smith & Associates, the demand for these switches is expected to grow by 12% annually over the next five years. This growth highlights their importance in both consumer products and industrial machines.

Expert Sarah Johnson, a leading figure in the switch manufacturing industry, emphasizes the versatility of Latching Push Button Switches. She states, “The shift to automation makes reliable controls essential.” This quote reflects the growing reliance on these switches in modern technology.

Despite their benefits, many designers overlook the nuances of choosing the right switch. Selecting a latching switch involves understanding circuit configurations and user interface requirements. It's crucial to consider factors like durability and responsiveness. The choices can be overwhelming, as options abound. However, being informed can lead to better decision-making. The right Latching Push Button Switch can enhance functionality and user experience significantly.

Understanding Latching Push Button Switches and Their Applications

Latching push button switches are essential in many electronic projects. They provide a simple on/off mechanism. These switches maintain their state after being pressed, making them ideal for applications like lighting and control panels. Understanding their function helps designers choose the right type. However, not all latching switches are created equal. Some may feel flimsy or unresponsive, leading to frustration during use.

Consider the applications you need. For instance, a switch in a hobby robot should be durable. The feel of the button matters as well. A poorly designed switch may cause misfires, complicating your project. Experimenting with different types can be enlightening, but it might take several attempts to find the right one. Documents can provide specifications, but real-world testing reveals much more.

Many users overlook the importance of size and mounting options. A switch that fits perfectly in one scenario might not work in another. Balancing functionality with design can sometimes be challenging. Reflecting on past projects, it's clear that even small details can make or break a build. The right latching push button switch can transform a project, but choosing wisely requires thought.

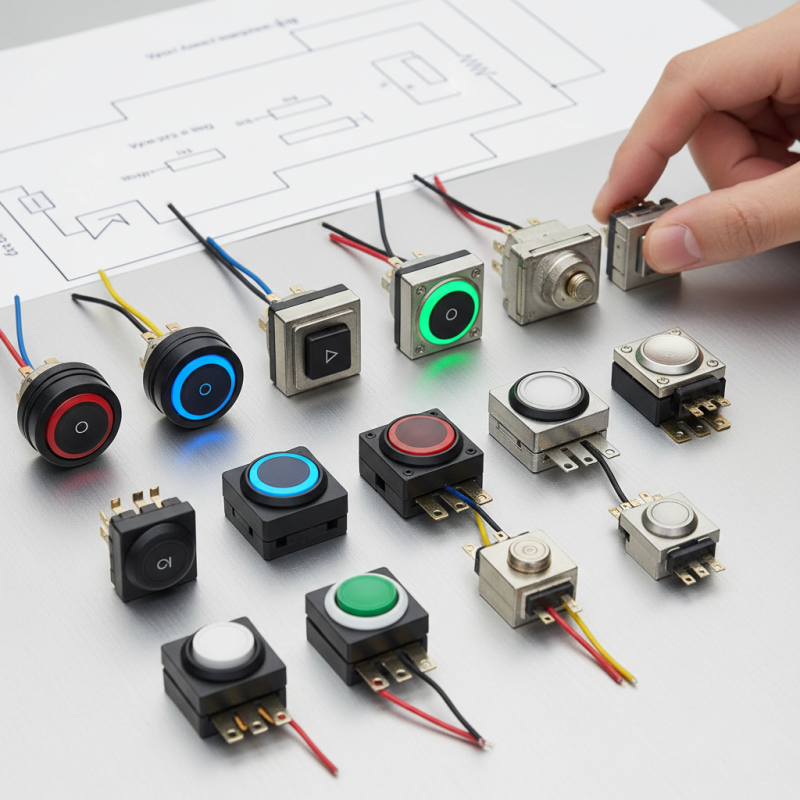

Top 10 Latching Push Button Switch Options for Your Projects

| Switch Type | Voltage Rating | Current Rating | Mounting Type | Material | Application |

|---|---|---|---|---|---|

| Metal Push Button | 12V | 10A | Panel Mount | Stainless Steel | Industrial Equipment |

| Plastic Push Button | 24V | 5A | Panel Mount | Plastic | Consumer Electronics |

| Waterproof Push Button | 12V | 8A | Panel Mount | Rubber | Outdoor Lighting |

| Illuminated Push Button | 5V | 2A | Panel Mount | Plastic | Control Panels |

| Tactile Push Button | 3.3V | 0.5A | Surface Mount | Plastic | Embedded Systems |

| High Current Push Button | 48V | 30A | Panel Mount | Metal | Automotive Applications |

| Mini Push Button | 12V | 3A | Surface Mount | Plastic | Portable Devices |

| Rocker Push Button | 120V | 15A | Panel Mount | Plastic | Household Appliances |

| Sealed Push Button | 12V | 10A | Panel Mount | Metal | Industrial Machinery |

Key Features to Consider When Selecting Push Button Switches

When selecting a latching push button switch, consider several key features. Durability is critical; look for switches that can withstand significant wear and tear. The electrical rating matters too. Ensure it matches the requirements of your project to avoid failures. Take note of the actuation force; it should provide a satisfactory click without requiring excessive strength.

Another essential feature is the illumination option. Some switches come with built-in lights for easy identification. This can be vital in low-light conditions. Size and design play a role as well; choose one that fits neatly into your project. Pay attention to mounting style, as some require specific housing dimensions.

Even small details impact functionality. Check the ratings for both AC and DC operations. This information can prevent complications later on. Accessibility is key in design too. Some designs may be challenging to reach in tight spaces. Reflect on your project's needs and the potential limitations of your selected switches. It’s easy to overlook these aspects, but they can affect the overall performance.

Top 10 Recommended Latching Push Button Switches for Various Projects

Latching push button switches are versatile components for various projects. They can control lights, motors, and other devices. Choosing the right switch can greatly affect your project's functionality. Here are some recommended options that may suit different applications.

Consider the size and mounting type when selecting a switch. Some are designed for through-hole installation, while others are surface-mounted. Look for options that offer different illumination styles. This can enhance visibility in darker settings. A momentary switch might seem appealing but lacks the latching feature many projects require.

The materials used in switches also matter. Durable switches can withstand frequent use. Plastic casings may wear quickly under stress. Metal options, while heavier, often provide a sturdier solution. Remember to assess the electrical ratings as well. Some switches might not handle higher currents. It’s an aspect easily overlooked but vital for safety. Slipping up here could lead to project failure. Choose wisely and test your selection before final implementation.

Comparative Analysis of the Best Latching Push Button Switches

When selecting latching push button switches for your projects, a comparative analysis reveals key features. These switches are vital for user interactivity. They stay in their last position until pressed again. This provides an easy way to control devices.

Consider factors like durability and sensitivity. Some switches feel great to press, while others might require more force. Testing a variety can help identify what fits your needs best. Look for options that offer a clear click sound. It adds assurance that your choice is effective.

Tips: Always pay attention to the mounting style. Some switches fit into panels seamlessly, while others need space. Think about the design; it should match your project aesthetics. Lastly, assess the power ratings. Choosing the wrong one could lead to frustration later on. Balancing all these needs can be a challenge, but it’s worth the effort for a quality outcome.

Installation Tips for Latching Push Button Switches in Your Projects

When working with latching push button switches, installation is key to ensuring reliable operation. Start by selecting the correct switch for your needs. Check the specifications, such as voltage and current ratings. This simple step can save headaches later.

Placement matters too. Position your switch where it's easy to access. Avoid tight spaces that make future adjustments tough. Testing the installation before finalizing is crucial. It helps catch any mistakes early.

Always double-check your wiring. Use proper connectors to avoid loose connections. Simple errors can lead to shorts or malfunctioning switches. Make sure to secure all components tightly. Sometimes, things feel rushed. Taking a moment to review can prevent future issues. Don’t underestimate proper labeling. Clear labels can streamline maintenance.

Related Posts

-

Discovering Top Quality Suppliers for Best Push On Off Switches Your Comprehensive Guide

-

Unleashing Excellence: Premium Micro Switch Push Buttons from China for Global Buyers

-

7 Tips for Choosing the Best Push Button On Off Switch for Your Application

-

Understanding the Mechanism: What is a Latching Push Button Switch and Its Applications

-

7 Essential Tips for Choosing the Right Latching Push Button Switch

-

Illuminate Your Control Experience with the Advantages of Illuminated Push Buttons for Enhanced Safety