7 Essential Tips for Choosing the Right Latching Push Button Switch

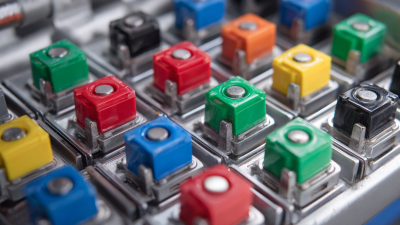

Choosing the right components for your electrical projects is crucial, and when it comes to switch mechanisms, a Latching Push Button Switch stands out as a reliable option. These switches not only provide a simple way to control devices but also ensure that they remain active without constant pressure, making them ideal for various applications. However, with a plethora of variants available, selecting the perfect latching push button switch can be daunting.

Choosing the right components for your electrical projects is crucial, and when it comes to switch mechanisms, a Latching Push Button Switch stands out as a reliable option. These switches not only provide a simple way to control devices but also ensure that they remain active without constant pressure, making them ideal for various applications. However, with a plethora of variants available, selecting the perfect latching push button switch can be daunting.

In this blog, we will explore seven essential tips to help you navigate through the myriad choices, focusing on factors such as pin compatibility, electrical ratings, and durability. By understanding these key aspects, you can make an informed decision that enhances the functionality and reliability of your projects.

Whether you’re a seasoned engineer or a DIY enthusiast, this guide will equip you with the knowledge needed to choose the right latching push button switch for your next endeavor.

Understanding the Importance of Quality Ratings in Push Button Switches

When selecting a latching push button switch, understanding the importance of quality ratings is crucial for ensuring reliability and durability in various applications. Quality ratings, which include parameters such as voltage rating, current rating, and environmental resilience, significantly impact the performance of the switch. According to a report from MarketsandMarkets, the global push button switch market is expected to reach $3.2 billion by 2025, highlighting the increasing demand for high-quality components that can endure rigorous operating conditions.

In industrial settings, switches with higher quality ratings can effectively reduce failure rates and downtime, contributing to overall operational efficiency. For instance, a push button switch rated for 10A at 250V may be more suitable for heavy machinery applications compared to a lower-rated counterpart. Additionally, switches that adhere to standards set by organizations such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) not only ensure safety compliance but also signify a level of quality assurance that can enhance the longevity of the product. In fact, research indicates that products meeting these stringent ratings can experience up to 50% fewer failures, underscoring the importance of investing in quality certifications when choosing the right latching push button switch for your needs.

Evaluating Electrical Specifications: Voltage and Current Requirements

When selecting a latching push button switch, evaluating electrical specifications, particularly voltage and current requirements, is crucial. Understanding the voltage rating of the switch is the first step in ensuring safety and functionality. The voltage rating signifies the maximum voltage that the switch can handle without risking failure or creating a hazardous situation. It's essential to choose a switch that matches or exceeds your application’s voltage requirements to prevent burnout and ensure reliability.

Next, consider the current rating. This value indicates how much electrical load the switch can carry without overheating or failing. Exceeding this limit can lead to short circuits or premature wear of the switch. It’s advisable to factor in a safety margin, considering that actual operating conditions may fluctuate. Additionally, think about the type of load being switched—whether it's resistive, inductive, or capacitive—since this can influence both the current requirement and the switch's performance. By meticulously evaluating these specifications, you ensure not only the longevity of the push button switch but also the overall safety and efficiency of your electrical system.

Assessing Environmental Resistance: IP Ratings and Their Significance

When choosing a latching push button switch for various applications, assessing environmental resistance is crucial, particularly regarding IP ratings. These ratings indicate the level of protection an electrical device has against dust and water ingress. For instance, an IP67-rated switch can endure immersion in water up to 1 meter for 30 minutes, making it suitable for harsh outdoor environments. This robustness is increasingly important as more industries recognize the role of equipment durability in maintaining operational efficiency amid challenging conditions.

In light of microbial dynamics highlighted in recent studies, focusing on material selection that minimizes microbial retention is vital. Research has shown that surfaces with higher antimicrobial properties can significantly reduce pathogen presence, which is particularly relevant in sensitive environments like schools and healthcare facilities. For instance, incorporating materials that are easier to clean and resist microbial colonization can enhance the overall hygiene of the environment, while also extending the lifespan of the switches. With environmental factors playing a significant role in antimicrobial resistance, ensuring that chosen components possess strong environmental ratings not only adheres to safety standards but also promotes a healthier ecosystem.

Material Selection: How Durability Affects Longevity and Performance

When selecting a latching push button switch,

material selection is paramount as it significantly impacts both longevity and performance.

According to a 2021 report by the Electronic Components Industry Association (ECIA), over 40% of switch failures can be attributed to material degradation.

Common materials used in switch construction include thermoplastics, metals, and silicone,

each offering unique advantages that affect durability. For instance, high-grade stainless steel switches can

withstand harsh environmental conditions and are resistant to corrosion, leading to a lifespan that may exceed 10 years in outdoor applications.

Moreover, the choice of materials can influence the switch's operational characteristics. The same ECIA report highlighted that switches made from

high-performance polymers maintain their tactile feedback and electrical conductivity better than lower-grade materials

even after extensive usage. In industrial settings, where switches experience high-frequency actuation, selecting materials that endure mechanical wear is crucial;

studies show that a premium material choice can enhance performance by up to 30%. Therefore, evaluating material

durability not only ensures a longer lifespan but also optimizes the functionality of latching push button switches in demanding applications.

Analyzing Installation Requirements: Space, Mounting, and Accessibility Considerations

When selecting a latching push button switch, understanding the installation requirements such as space, mounting, and accessibility is crucial. First, consider the available space where the switch will be installed. Compact areas may restrict the type and size of the switch, necessitating a more compact design. Additionally, electrical and mechanical components around the installation site must be evaluated to ensure sufficient room for the wiring and operation of the switch without causing interference.

Mounting options should also be primary considerations. Different switches come with various mounting styles, including panel mount, surface mount, or even snap-in configurations. Ensuring the selected switch can be securely fitted while providing the necessary durability for its application is essential. Finally, accessibility cannot be overlooked. The switch should be placed where it can be easily reached by users, particularly in emergency situations. Factors like height, reachability, and visibility are key in preventing user errors and enhancing safety in operation. By focusing on these aspects, you can choose a latching push button switch that meets both functional requirements and user convenience effectively.

Related Posts

-

Leading Push Button Starter Switch Manufacturers in China at the 137th Canton Fair

-

5 Reasons Why the Best Push Button Starter Switch Will Transform Your Operations

-

2025 Market Insights: The Rise of Best Push Button Starter Switch in Global Manufacturing

-

Unleashing Excellence: Premium Micro Switch Push Buttons from China for Global Buyers

-

2025 Industry Insights: Ultimate Checklist for Selecting the Best Micro Switch Push Buttons

-

7 Tips for Choosing the Best Push Button On Off Switch for Your Application