Your Essential Guide to Micro Limit Switches: Choosing the Right One for Your Application

In the realm of automation and precision engineering, the significance of selecting the right components cannot be overstated. Among these components, the Micro Limit Switch has emerged as a critical element, enabling reliable and accurate control in various applications. According to a recent industry report by MarketsandMarkets, the global limit switch market is projected to reach USD 2.37 billion by 2025, growing at a CAGR of 5.7%. This growth reflects the increasing demand for automation in manufacturing, coupled with the rising need for safety and reliability in control systems. As industries strive for efficiency and precision, understanding the nuances of Micro Limit Switches, including their specifications and applications, becomes vital for engineers and decision-makers alike. This essential guide will help you navigate the complexities of choosing the right Micro Limit Switch tailored to your specific application needs.

Understanding Micro Limit Switches: Definition and Functionality

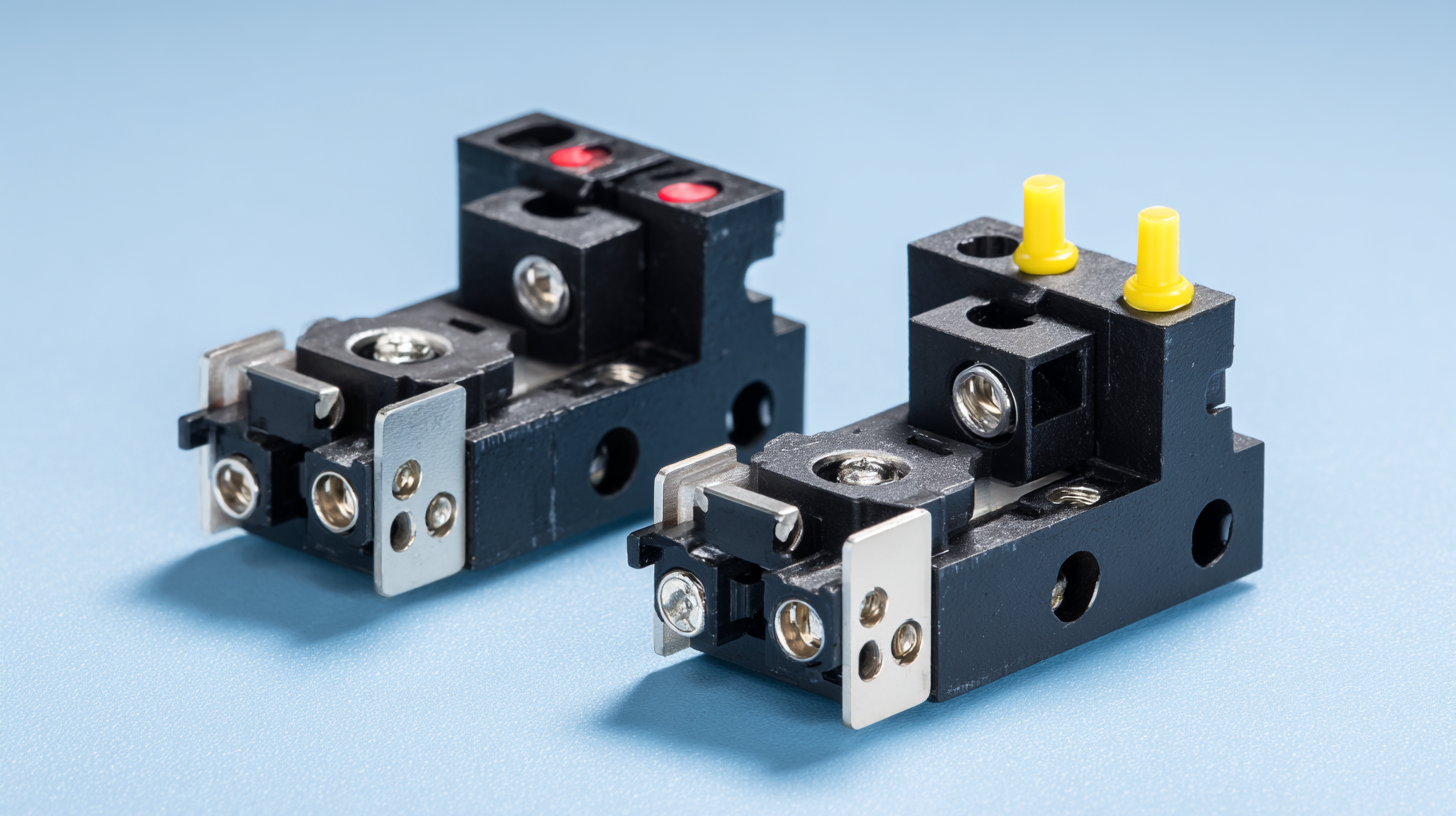

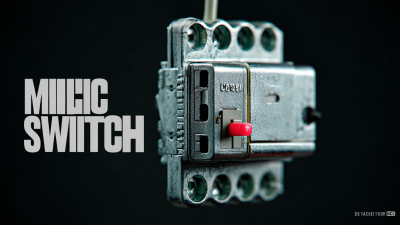

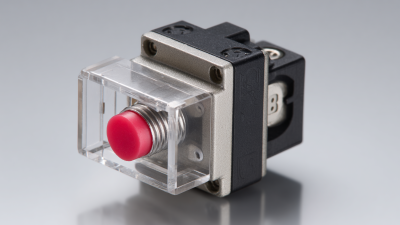

Micro limit switches are essential components in various applications, known for their compact size and reliable performance. These switches function as electromechanical devices that detect the position of an object, signaling when it reaches a predetermined location. When the actuator (often a lever or a push-button) is pressed, the internal mechanism closes or opens the electrical circuit, allowing or interrupting the flow of electricity. This feature makes micro limit switches ideal for automation systems where precision and space-saving designs are crucial.

The versatility of micro limit switches means they can be utilized in a wide range of scenarios, from industrial machinery to consumer electronics. Understanding the functionality of these switches is vital when selecting the right type for your application. Considerations such as the switch's actuation force, travel distance, and electrical ratings will influence performance and reliability. Additionally, the environmental conditions, such as exposure to dust, moisture, or extreme temperatures, should also be taken into account to ensure optimal operation and longevity in your specific use case.

Your Essential Guide to Micro Limit Switches: Choosing the Right One for Your Application

| Feature | Description | Typical Applications |

|---|---|---|

| Contact Type | Single Pole Double Throw (SPDT), Normally Open (NO), Normally Closed (NC) | Machine control, automation systems |

| Operating Force | Varies from low to high force, typically between 0.5N to 6N | Robotics, safety equipment |

| Travel Distance | Short travel, often less than 5 mm | Automated doors, conveyor systems |

| Mounting Type | Panel mount, PCB mount, bracket mount | Industrial equipment, electronic devices |

| Electrical Rating | Varies widely, often rated for 10A at 250VAC | Control panels, machinery |

| Environmental Protection | IP ratings ranging from IP65 to IP67 | Outdoor applications, harsh environments |

Key Types of Micro Limit Switches and Their Applications

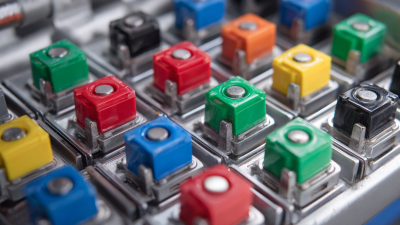

When it comes to micro limit switches, understanding the key types and their applications is essential for selecting the right component for your specific needs. The most common types of micro limit switches include snap-action switches, roller-lever switches, and plunger switches. Snap-action switches are popular in industrial applications due to their fast actuation and durability. They are ideal for use in safety systems, automation equipment, and any scenario where precise control is critical.

Roller-lever switches, on the other hand, provide a mechanical advantage for applications requiring higher force activation. They are commonly used in conveyor systems and other machinery where movement is essential. Additionally, plunger switches are versatile and can be utilized in various applications, such as door systems, where detecting the presence or absence of an object is necessary. Each type of micro limit switch offers unique advantages depending on your application, making it crucial to evaluate the specific requirements to choose the most suitable switch.

Factors to Consider When Choosing a Micro Limit Switch

When selecting a micro limit switch for your application, several crucial factors come into play to ensure optimal performance and reliability. First and foremost, understanding the operating environment is essential. Micro limit switches are often utilized in compact spaces where reliability is critical, such as in micro trucks, which are projected to see immense growth in market value, increasing from $120.62 million in 2024 to $252.3 million by 2032, reflecting a compound annual growth rate of 9.66%. This highlights the importance of robust components in emerging industries.

Another significant factor to consider is the switch's electrical specifications. Ensure the switch can handle the required voltage and current levels of your specific application to avoid potential failures. With the rise of electric micro vehicles, for example, where components need to endure various operational stresses, choosing a limit switch with the right specifications can make a notable difference in performance and longevity. The latest reports indicate that micro-sized electric vehicles can achieve a range of 50 to 300 kilometers depending on different factors, underscoring the demand for high-quality, reliable micro limit switches tailored to these applications.

Your Essential Guide to Micro Limit Switches: Choosing the Right One for Your Application

Installation Tips for Micro Limit Switches in Various Settings

When it comes to installing micro limit switches, understanding the diverse settings and applications is crucial for optimal performance. These switches, known for their compact form and precision, are often utilized in industrial automation, robotics, and CNC machinery. According to recent data, micro limit switches can enhance operational efficiency by up to 30% when integrated correctly, making them essential for real-time position tracking of moving components.

In various settings, the installation of micro limit switches requires careful consideration of connection types and environmental factors. For example, new compact limit switch options provide various electrical connection types, including quick disconnect features that facilitate easy installation and maintenance. Moreover, ensuring that the switch is properly aligned with the mechanical components it monitors is vital to prevent miscommunication and potential malfunctions. Adhering to best practices in placement and adjustment can significantly reduce downtime, promoting a smoother workflow in manufacturing processes.

Common Issues and Troubleshooting for Micro Limit Switches

When using micro limit switches, it’s important to be prepared for common issues that may arise during operation. One frequent problem is the switch becoming unresponsive due to wear or environmental factors. Dust, moisture, and oils can accumulate on the switch, leading to contact failure. Regular maintenance, including cleaning and inspection, is crucial to ensure these switches function properly in demanding environments.

When using micro limit switches, it’s important to be prepared for common issues that may arise during operation. One frequent problem is the switch becoming unresponsive due to wear or environmental factors. Dust, moisture, and oils can accumulate on the switch, leading to contact failure. Regular maintenance, including cleaning and inspection, is crucial to ensure these switches function properly in demanding environments.

Another common issue is incorrect installation, which can lead to malfunction or premature failure. Misalignment of the switch and actuator can prevent the switch from being activated, causing the entire system to fail. It is essential to follow the manufacturer's guidelines for mounting and alignment. Additionally, checking for proper electrical connections can prevent short circuits that might damage the switch. By addressing these issues through proper installation and maintenance, users can enhance the longevity and reliability of micro limit switches in various applications.

Related Posts

-

Setting the Benchmark for Best Micro Switch On Off with Industry Standards

-

Ultimate Guide to Selecting the Best Micro Switch Button for Global Manufacturing Success

-

How to Choose the Best Micro Switch for Your Industrial Automation Needs: A Comprehensive Guide

-

2025 Industry Insights: Ultimate Checklist for Selecting the Best Micro Switch Push Buttons

-

What is a Micro Switch Push Button and How it Enhances Device Performance in Automation

-

15 Best Push Button On Off Solutions for Global Buyers