How to Choose the Right Dpdt Rocker Switch for Your Project?

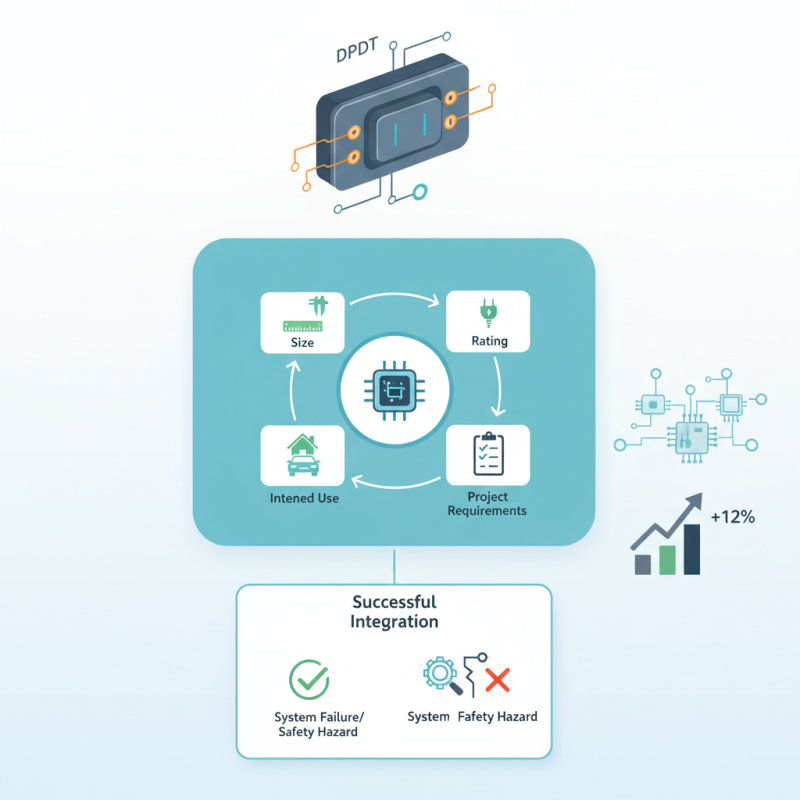

Choosing the right DPDT rocker switch for your project can be critical. According to a recent report by the Electronic Components Industry Association, the demand for specialized switches has grown by 12% in the last year. This growth signals a rising interest in custom electronic projects, where specific requirements are key.

DPDT rocker switches are versatile components. They control two circuits with a single action, improving efficiency. Many industries rely on this type of switch. For example, automotive and home automation sectors use them frequently. However, selecting the right DPDT rocker switch can be challenging. With numerous options available, making the right choice requires careful consideration.

Factors such as size, rating, and intended use matter. It's essential to match the switch's specifications to your project needs. A mismatch can lead to system failures or safety hazards. Consider your project's unique requirements thoroughly. This process may seem straightforward, yet it can lead to unexpected complications if overlooked.

Understanding DPDT Rocker Switches: Types and Features

When selecting a DPDT rocker switch, understanding the types and features is crucial. DPDT stands for Double Pole Double Throw. This type of switch can control two circuits. It offers versatile options for connecting devices. You can find many styles, from slim designs to larger, more robust models.

One popular feature is LED illumination. An illuminated switch enhances visibility. This can be especially useful in low-light conditions. Additionally, consider the material of the switch. Some are more durable than others. The quality of materials affects longevity.

**Tip:** Check the amperage and voltage ratings. Make sure these match your project requirements. Underestimating can lead to serious issues.

Another aspect is the mounting style. Panel mount or surface mount options vary in installation ease. Each has its pros and cons. Surfaces may require cutouts, while panel mounts can be straightforward.

**Tip:** Think about the environment. If the switch will face moisture, look for water-resistant options. This can save you future headaches.

In conclusion, take time to evaluate your options. Understanding your specific needs will lead to a better choice.

Factors to Consider When Choosing a DPDT Rocker Switch

Choosing the right DPDT rocker switch can be challenging. Various factors come into play, influencing the switch's performance and reliability. One key consideration is the electrical rating. A switch with the right voltage and current ratings ensures optimal operation. According to industry standards, a typical DPDT switch can handle up to 15 amps at 120 volts. Exceeding these limits could lead to failure.

Another important factor is the contact configuration. Different configurations offer various functionalities. For example, a DPDT switch can control two different circuits or directions of a motor. This versatility is essential for many projects. However, improper understanding of circuit needs can lead to inefficient designs. It's crucial to map out your requirements clearly.

A switch's physical size and mounting style also matter. Many projects have space constraints, making compact switches preferable. Industry data suggests that over 25% of projects fail due to poor fitment and compatibility issues. Ignoring these aspects can result in additional costs and delays. Thoughtful consideration of these factors ensures better alignment with project goals.

Step-by-Step Guide to Wiring a DPDT Rocker Switch

Wiring a DPDT rocker switch can be straightforward. This switch type is ideal for controlling two circuits. Start by gathering tools: wire cutters, a screwdriver, and electrical tape. You’ll also need wires that fit your project.

Remove the cover of the switch and expose the terminals. There are six terminals, usually arranged in a 2x3 format. Identify the center terminals; these are your power input. The outer terminals connect to your devices. Often, people get confused about which wire goes where. Using a diagram can help.

Strip the wire ends carefully to avoid fraying. Connect the power wires to the center terminals. Then, connect devices to the outer terminals. It’s easy to mix them up when you’re wiring in a hurry. After connection, secure everything with electrical tape. Always double-check your connections. Mistakes can lead to short circuits. Testing your setup before finalizing is crucial. If something doesn’t work, steps may need reevaluation. Keep this process methodical for better clarity.

| Switch Type | Current Rating | Voltage Rating | Size (mm) | Mounting Style | Typical Applications |

|---|---|---|---|---|---|

| DPDT Rocker Switch | 5A | 250V AC | 30 x 20 | Panel Mount | Home Appliances |

| DPDT Toggle Switch | 10A | 125V AC | 25 x 15 | Through Hole | Industrial Equipment |

| Mini DPDT Rocker Switch | 3A | 125V AC | 22 x 12 | Surface Mount | Toys, Small Devices |

| Heavy Duty DPDT Switch | 20A | 480V AC | 40 x 30 | Panel Mount | Machinery, Motor Control |

Applications of DPDT Rocker Switches in Various Projects

DPDT rocker switches are versatile components used in many projects. Their primary application lies in toggling between two circuits, making them ideal for various electronics and electrical tasks. For instance, they facilitate direction control in motors. A recent industry report indicates that the demand for these switches is projected to grow by 5% annually, reflecting their increasing use in automation and robotics.

In lighting applications, DPDT rocker switches can control multiple light sources. This functionality is vital for creating adjustable ambiance in smart homes. Moreover, these switches are also instrumental in audio equipment, allowing users to switch between different sound sources effortlessly. When you're selecting a switch, consider not just your current needs but also potential future applications.

Tips: Always check the rated current and voltage of the switch. This ensures your project won’t face power issues. Integrate user-friendly designs to enhance functionality. While selecting components, be mindful not to overlook the physical size of the switch that may restrict placement in compact spaces. It's essential to reflect on how the complexity of your project may increase with over-engineering. Balance is key.

Applications of DPDT Rocker Switches in Various Projects

This chart presents the various applications of DPDT rocker switches across different projects, highlighting their usage in various industries.

Maintenance Tips for Ensuring Longevity of DPDT Rocker Switches

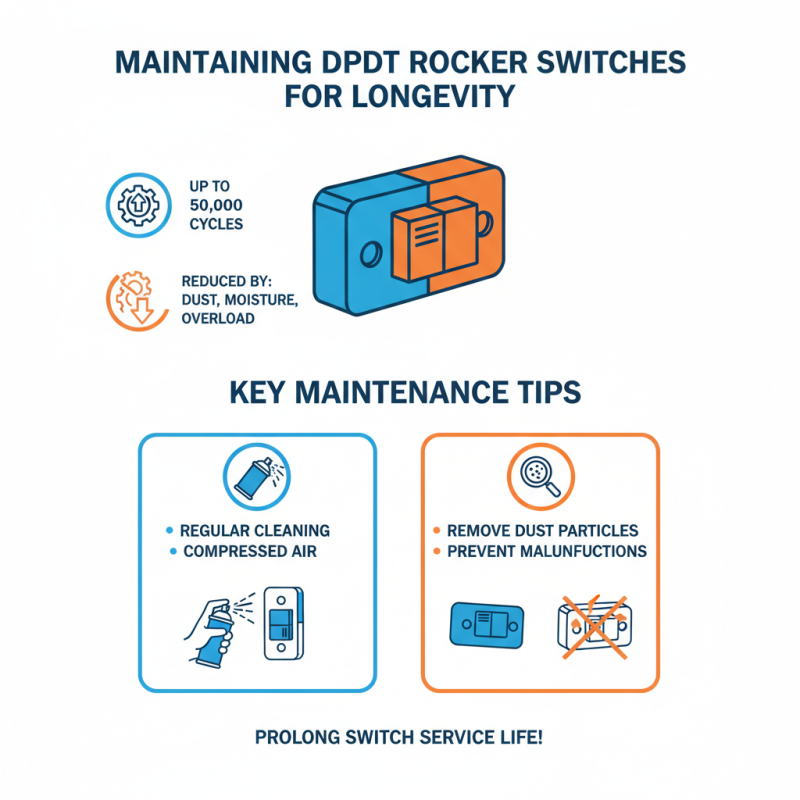

Maintaining DPDT rocker switches is crucial for their longevity. These switches often have a lifespan of up to 50,000 cycles. However, factors like dust, moisture, and electrical overload can significantly reduce their service life. Regular cleaning is essential. A simple blow of compressed air can remove dust particles that accumulate in hard-to-reach areas. This small action can prevent potential malfunctions.

Temperature control also plays a vital role. DPDT switches operate best in moderate conditions. High temperatures can cause internal components to degrade faster. If your project is in a heated environment, consider ways to provide additional cooling. Ambient temperature should ideally be kept between -10°C and 50°C. Keeping switches cool can extend their functionality.

In environments with fluctuating power, use surge protectors. Sudden electrical spikes can damage switches instantly. Regularly inspecting connections can help identify any loose or corroded points. Neglecting these checks could result in failures that disrupt your project. Even a small detail can have a significant impact. Prioritizing maintenance will not only save time but also money in the long run.

Related Posts

-

Top Strategies for Sourcing High Quality Dpdt Rocker Switches in Competitive Markets

-

Understanding the Benefits of Using Led Rocker Switches in Modern Devices

-

2025’s Top 10 Waterproof Rocker Switches for Ultimate Durability and Performance

-

Leading Push Button Starter Switch Manufacturers in China at the 137th Canton Fair

-

15 Best Push Button On Off Solutions for Global Buyers

-

How to Choose the Right Momentary Push Button Switch for Your Project