How to Choose a Dpdt Rocker Switch for Your Project?

Choosing the right Dpdt Rocker Switch is crucial for your project. These switches control the flow of electricity efficiently. They are used in various applications, from powering lights to controlling motors. Understanding their specifics can help you make an informed decision.

Consider the size and shape of the switch. A compact design may fit better in tight spaces. Look at the electrical specifications too. Ensure it can handle the voltage and current. If the switch doesn’t match your needs, it can lead to failures.

Selecting a Dpdt Rocker Switch involves balancing aesthetics and functionality. Sometimes, you may prefer a switch that looks good but doesn’t meet performance standards. Reflect on your choices to ensure the switch complements your project's requirements.

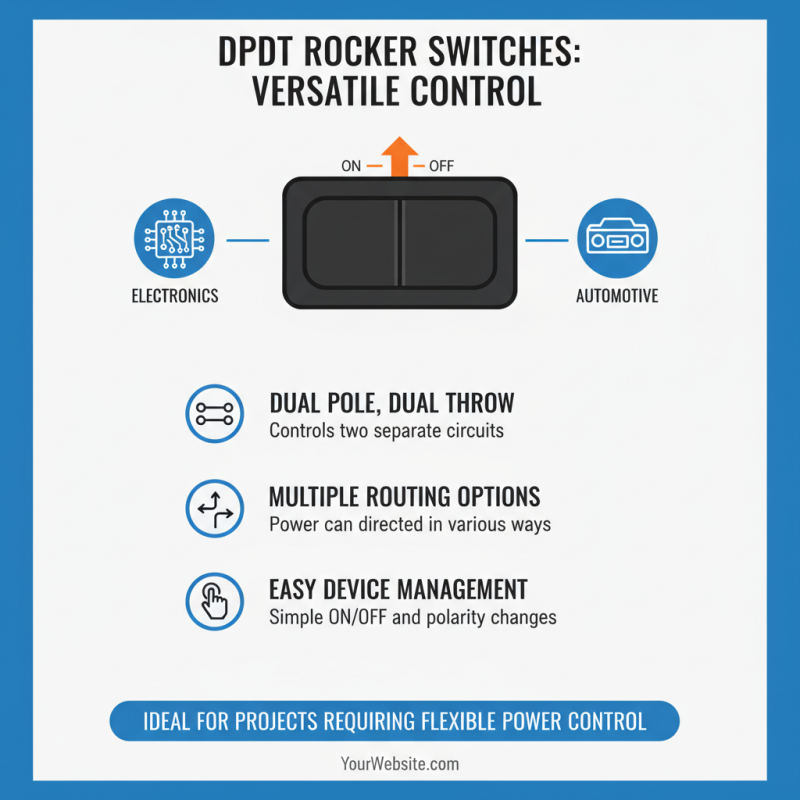

Understanding DPDT Rocker Switches and Their Applications

DPDT rocker switches play a vital role in various applications. They are designed to control multiple devices with ease. These switches have two poles and can route power in multiple ways. Their versatility makes them ideal for various projects, from electronics to automotive uses.

When selecting a DPDT rocker switch, consider your project's specific requirements. The switch's voltage and current ratings are crucial. Size and mounting type also matter. You may want a compact switch for tight spaces. A heavy-duty switch is better for high-power applications.

While it seems straightforward, choosing a DPDT switch can be tricky. Pay attention to details like the switch's action and feel. You might find some switches too stiff, while others are too loose. Trial and error is often part of the process. It's essential to experiment before finalizing your choice.

Key Specifications to Consider When Choosing a DPDT Rocker Switch

When selecting a DPDT rocker switch, several key specifications should guide your decision. Start by examining the voltage and current rating. Most switches handle standard ratings well, but it's essential to ensure the chosen switch suits your application. For example, a common rating is 15A at 125V AC. However, if your project involves higher power, consider options rated at 20A or 250V AC.

Next, think about the physical dimensions. Space constraints in your project may limit switch sizes. Many DPDT rocker switches fit in compact setups, but check the depth, width, and height to avoid compatibility issues. A study indicated that nearly 30% of design flaws come from miscalculations in component size.

Also, consider the actuation force and travel distance. A switch that requires too much force can lead to user frustration. Conversely, a too-sensitive switch may activate unintentionally. Ninety percent of engineers report switching issues affecting user experience. Balancing these specifications is crucial for usability in real-world applications.

Evaluating the Electrical Ratings: Voltage and Current in Your Project

When selecting a DPDT rocker switch, considering the electrical ratings is crucial. Voltage and current determine the switch's capacity for your project. If you exceed these ratings, you risk damaging the switch or causing unsafe conditions. Always check the specifications carefully.

It's essential to match the voltage rating of the switch with your project needs. For example, if your device runs on 12 volts, ensure the switch can handle at least that amount. Current ratings are equally important. A switch rated for three amps won't work for devices that draw five amps.

**Tips:** Always err on the side of caution. Choose a switch with a higher rating than you need. When in doubt, consult technical resources. Test the switch during installation. A simple oversight can lead to larger issues later. Reflecting on your initial choice can save time and resources.

Evaluating Electrical Ratings for DPDT Rocker Switches

Physical Dimensions and Mounting Options for DPDT Rocker Switches

When selecting a DPDT rocker switch, consider the physical dimensions carefully. The size of the switch impacts the overall design of your project. A compact switch may fit tight spaces but could be difficult to operate. Larger switches provide better accessibility but might not suit smaller enclosures. Assess the available space before making your choice.

Mounting options are also crucial. Some switches require panel mounting with specific cutouts, while others may use screw or snap-in methods. Pay attention to the thickness of the panel where you will install the switch. Using a switch that does not match your panel thickness can lead to challenges. Sometimes, a switch might fit perfectly, but its operation could feel flimsy.

Lastly, test the switch type you choose. Some DPDT rocker switches have a firm feel, while others may feel a bit loose. This can affect user experience. If the switch is too stiff or too easy to toggle, it might not be ideal for your needs. A crucial step is to visualize the interaction. Will your users easily understand how to use it? Always reflect on whether the switch enhances or detracts from your project's design.

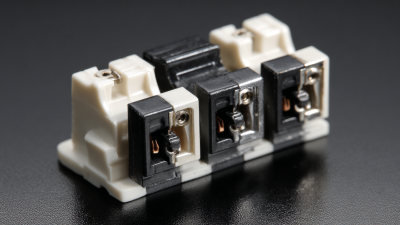

Comparing Material Quality and Durability for Long-term Use

When choosing a DPDT rocker switch for your project, material quality and durability are crucial factors. A report from the Electronics Components Association states that over 30% of component failures are due to poor material choices. This underscores the importance of selecting switches made from high-grade plastics and robust metals. Look for materials like nylon or polycarbonate, which offer good thermal stability and resistance to impact.

Durability often translates to long-term reliability. Research indicates that switches using silver contacts can withstand more cycles than those with inferior materials. For instance, gold-plated contacts can handle about 10,000 operations, while standard contacts may only endure 5,000. Identifying the right finish ensures your project can last. Many manufacturers provide testing standards. However, some users overlook these details. Ignoring them could lead to premature failures.

Corrosion resistance also plays a significant role. Environmental factors can degrade switches made from low-quality materials. A study by the Institute of Electrical and Electronics Engineers reveals that 15% of switch breakdowns occur due to corrosion. Be aware that cheaper options might sell well, but they could cost more in the long run. Quality materials protect your investment. Evaluating a switch's specifications is vital to avoid future regrets.

How to Choose a Dpdt Rocker Switch for Your Project? - Comparing Material Quality and Durability for Long-term Use

| Switch Type | Material | Durability (Cycles) | Operating Temperature (°C) | Rating (Amps) |

|---|---|---|---|---|

| Standard DPDT | Plastic | 10,000 | -20 to 80 | 10 |

| Heavy Duty DPDT | Metal | 50,000 | -40 to 85 | 20 |

| Mini DPDT | Plastic | 5,000 | -10 to 70 | 5 |

| Waterproof DPDT | Rubber/Plastic | 30,000 | -20 to 60 | 8 |

| Illuminated DPDT | Plastic | 15,000 | -20 to 70 | 10 |

Related Posts

-

Unlocking the Secrets of Best Momentary Rocker Switch Specifications and Usage Techniques

-

Exploring Innovative Alternatives to the Best Double Rocker Switch for Your Projects

-

Common Issues Faced with Rocker Switch Devices in Everyday Use

-

Understanding the Versatility of Dpdt Rocker Switches in Modern Electrical Applications

-

Maximizing Efficiency with Momentary Rocker Switches in Modern Automation Systems

-

Top 10 Benefits of Using a 3 Way Rocker Switch for Your Home Wiring