How to Choose the Right Momentary Rocker Switch for Your Project

When embarking on a new project that involves electrical components, one crucial decision lies in selecting the appropriate Momentary Rocker Switch. This versatile switch type is known for its ability to facilitate on/off operation temporarily, making it a popular choice for a variety of applications, from automotive controls to home automation systems. Understanding the specific requirements of your project and how a Momentary Rocker Switch can meet those needs is essential for achieving both functionality and reliability.

Selecting the right Momentary Rocker Switch requires careful consideration of several factors. These include the switch's electrical ratings, form factor, actuation force, and the intended environment. Additionally, the aesthetic appeal of the switch can play a vital role, especially in applications where user interaction is frequent. By assessing these elements, you can ensure that the Momentary Rocker Switch not only fits technically but also aligns with the overall design and functionality of your project.

In this guide, we will explore the key considerations and characteristics of Momentary Rocker Switches that will help you make an informed decision. Whether you're a hobbyist or a professional engineer, understanding how to choose the right switch can greatly enhance the performance and user experience of your project.

Understanding the Basics of Momentary Rocker Switches and Their Applications

Momentary rocker switches are essential components in various electronic projects, allowing users to control circuits with a simple push. Understanding the basics of these switches begins with recognizing their operation; they are designed to remain in an active state only while being pressed. This feature makes them ideal for applications requiring temporary engagement, such as in power tools, gaming consoles, and automotive controls. When released, the switch returns to its default position, ensuring safety and efficiency in circuit operation.

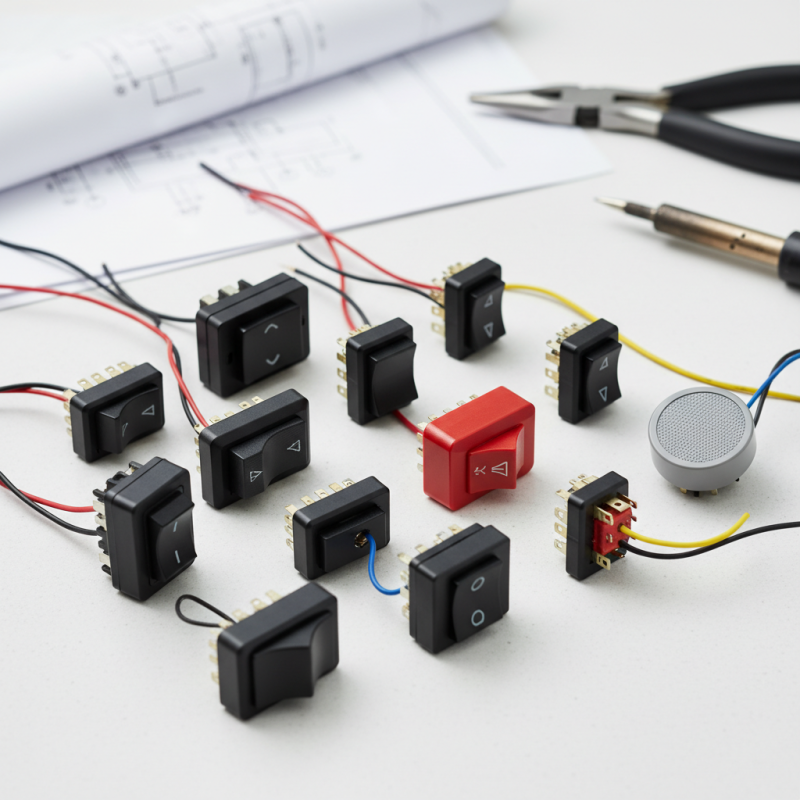

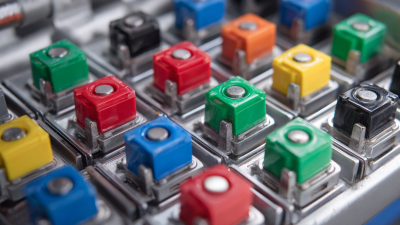

The versatility of momentary rocker switches extends to their design and functional applications. They come in various sizes, colors, and configurations, which can enhance user interaction in a project. For instance, illuminated switches provide visual feedback, making them suitable for use in low-light conditions. Additionally, their ability to handle different voltage and current ratings means they can be integrated into both high- and low-power applications. When selecting the right switch for a particular project, considering the switch's specifications and the specific requirements of the application is crucial to ensure optimal performance and reliability.

Momentary Rocker Switch Applications

Key Specifications and Ratings to Consider When Selecting a Rocker Switch

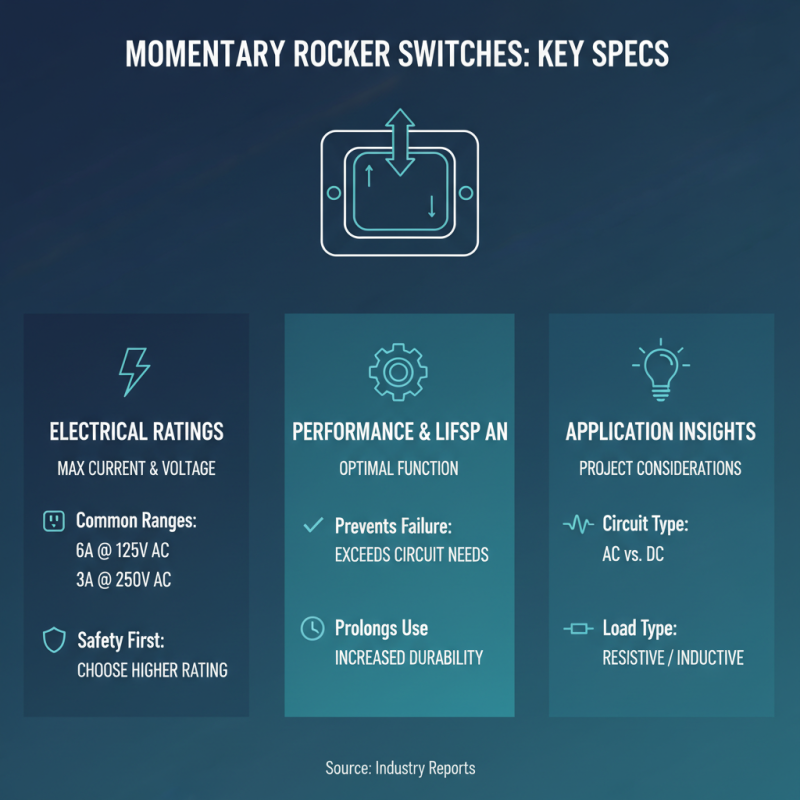

When choosing a momentary rocker switch for your project, understanding key specifications and ratings is critical to ensuring optimal performance and safety. One of the foremost considerations is the switch's electrical rating, which typically indicates the maximum current and voltage the switch can handle. According to industry reports, specifications may range from 6A at 125V to 3A at 250V, depending on the application. Choosing a switch rated higher than your circuit’s requirements can prevent failure and prolong the switch's lifespan.

Another crucial factor is the operational life of the switch, often quantified in terms of cycles. A standard rocker switch may have an operational life ranging from 10,000 to over 1 million cycles, depending on construction quality. Reports suggest that switches designed for high-frequency operations require higher cycle ratings to maintain reliability over time. It's also essential to consider the environmental factors, such as moisture and dust exposure, which may necessitate switches with specific IP (Ingress Protection) ratings to ensure durability.

Tips: Always double-check both the contact material and actuator type of your selected rocker switch, as these can significantly affect the switch's performance in various environments. Additionally, implementing switches with visual indicators may enhance usability, especially in complex setups. Ensure you assess the switch's mounting style to confirm compatibility with your project design.

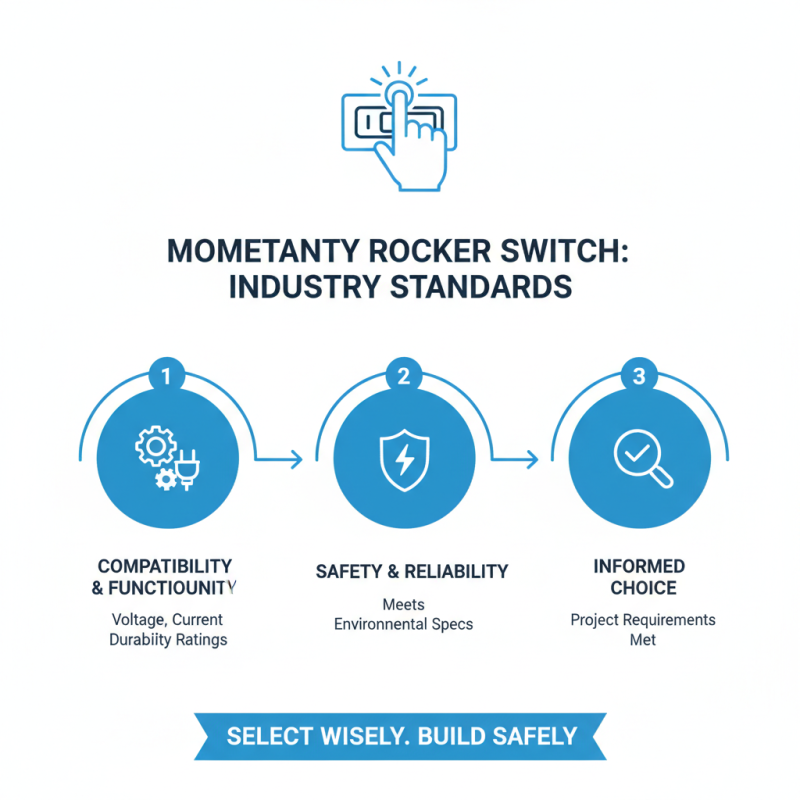

Industry Standards for Momentary Rocker Switches: What You Need to Know

When selecting a momentary rocker switch for your project, understanding industry standards is crucial for ensuring compatibility and functionality. Momentary rocker switches are widely used in various applications, and they come with specific ratings for voltage, current, and mechanical durability. These standards dictate not only the switch's performance but also its safety and reliability in different environments. Familiarizing yourself with these ratings will help you make a more informed choice that meets your project's requirements.

In addition to electrical specifications, learning about the different types of momentary rocker switches, their intended uses, and their operational features is essential. Look for switches that adhere to relevant industry certifications, which indicate compliance with safety and quality standards. It’s important to consider factors such as the switch's physical size, the type of activation (such as a push or toggle action), and any additional features like illumination. By taking the time to understand these industry standards, you can ensure that the momentary rocker switch you choose will be reliable, safe, and suitable for your specific application.

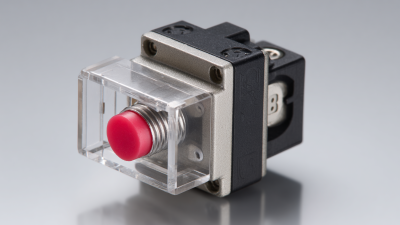

Common Materials and Design Features of Momentary Rocker Switches

When selecting a momentary rocker switch for your project, understanding common materials and design features is crucial. Momentary rocker switches are typically constructed from durable materials such as thermoplastics, metal alloys, and rubber. Thermoplastic enclosures provide a lightweight yet resilient option that can withstand daily wear and tear, while metal housing adds robustness and a premium feel. The choice of material not only affects the switch's longevity but also its ability to resist environmental factors such as moisture and temperature variations.

The design of the rocker switch itself plays a significant role in its functionality. Many switches offer varying actuator heights, tactile feedback, and illumination options. According to industry reports, approximately 30% of users prefer switches with integrated LED indicators for visibility in low-light conditions. Additionally, the choice of actuator shape, whether rounded or angled, can influence user ergonomics and ease of use.

Tips: When choosing a momentary rocker switch, consider the operating environment. If the switch will be exposed to moisture, opt for models that feature water-resistant designs. Furthermore, ensure that the switch's lifespan aligns with your project's expected usage. A switch rated for 10,000 cycles may be suitable for casual applications, while high-frequency use may require options rated for 50,000 cycles or more.

Matching Switch Types to Project Requirements: A Practical Guide

When selecting a momentary rocker switch for your project, it's essential to match the switch type to your project requirements. According to a recent industry report by MarketsandMarkets, the global rocker switch market is projected to grow at a CAGR of 8.5% between 2021 and 2026, driven by increasing demand for compact, efficient switching solutions in consumer electronics and industrial applications. The choice of switch not only affects the functionality but also the durability and user experience of the end product.

One key consideration is the electrical specifications, including voltage, current ratings, and the switch's intended application. For example, a switch designed for low-voltage circuits might not be suitable for high-voltage environments, leading to potential failures. Additionally, environmental factors such as exposure to moisture or dust can influence the selection process. According to the IEEE, inappropriate switching components can lead to a significant increase in device failure rates, emphasizing the importance of choosing the right momentary rocker switch that meets both the operational and environmental conditions of your project. Understanding these requirements allows engineers and designers to optimize their designs, ensuring reliability and performance in the intended application.

Related Posts

-

The Rise of Push On Off Switch Technology in Smart Home Automation Systems

-

Innovative Solutions for Best Micro Switch Push Button Applications

-

2025 Market Insights: The Rise of Best Push Button Starter Switch in Global Manufacturing

-

2025 Industry Insights: Ultimate Checklist for Selecting the Best Micro Switch Push Buttons

-

What is a Micro Switch Push Button and How it Enhances Device Performance in Automation

-

How to Choose the Right Momentary Push Button for Your Project